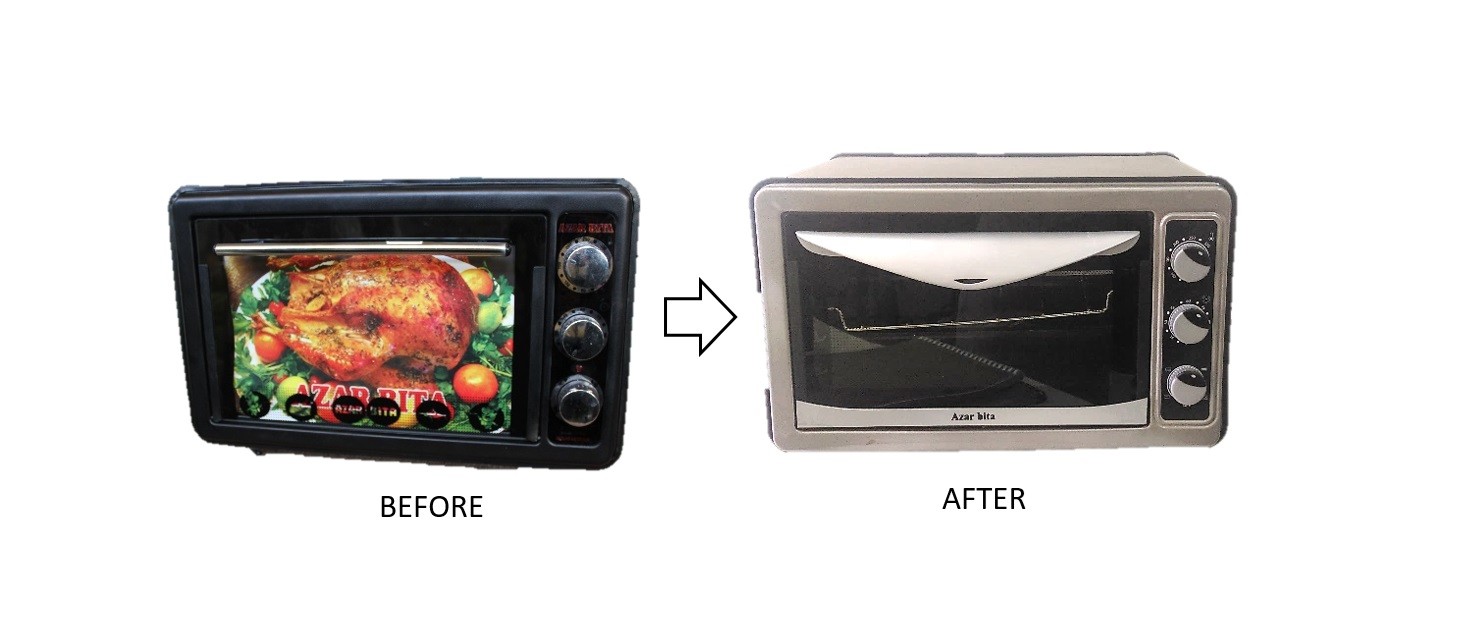

Oven Toaster Redesign

Led a design team at Azar Bita Tabriz Factory through a six-month development process, focusing on both functionality and aesthetics. Successfully transitioned the oven toaster project to mass production, resulting in a product that was launched and made available for customer purchase.

My Role:

Design Manager at Azar Bita Tabriz Factory

Project Duration:

6 Months in 2018

Challenge

Lack of Internal Oven Light: The absence of an internal light in the oven made it difficult for users to monitor the cooking process, leading to burnt food and energy wastage.

Small Distance Between Heating Element and Tray: The small distance between the upper heating element and the tray caused food to come into contact with the element, resulting in burning.

Poor Oven Handle Design: The oven handle was poorly designed, making it easy for users to burn their hands while opening or closing the oven.

Inadequate Insulation of Oven Body: The oven body would become excessively hot due to inadequate insulation, leading to burns when touched by users.

Unsafe Internal Wiring: Exposed wires inside the oven posed a risk of electric shock to users

Solution

Installation of Internal Oven Light: A light was installed inside the oven to allow users to see the food clearly during cooking, preventing it from burning.

Increased Distance Between Heating Element and Tray: The distance between the upper heating element and the tray was increased to prevent food from burning by touching the element.

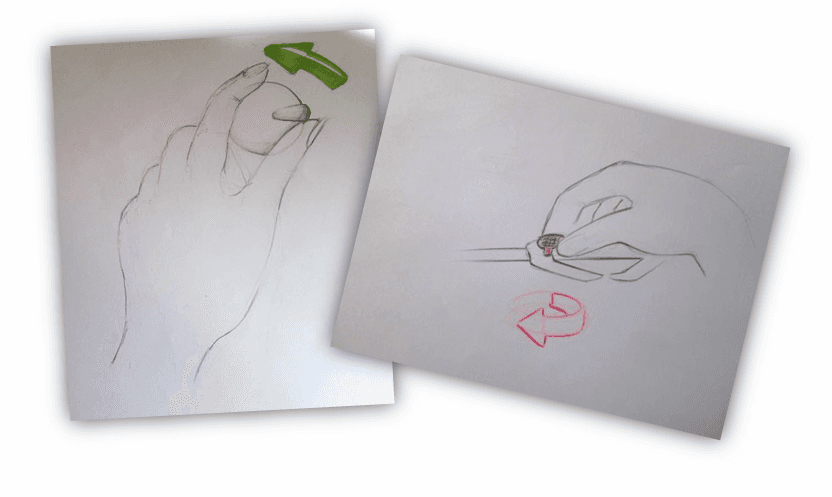

Redesigned Oven Handle: The oven handle was redesigned with improved ergonomics and heat resistance, reducing the risk of burns.

Enhanced Insulation of Oven Body: The oven body was insulated more effectively to prevent excessive heating, ensuring that the surface remains cool to the touch.

Improved Internal Wiring Safety: The internal wiring was properly insulated and secured to eliminate the risk of electric shock.

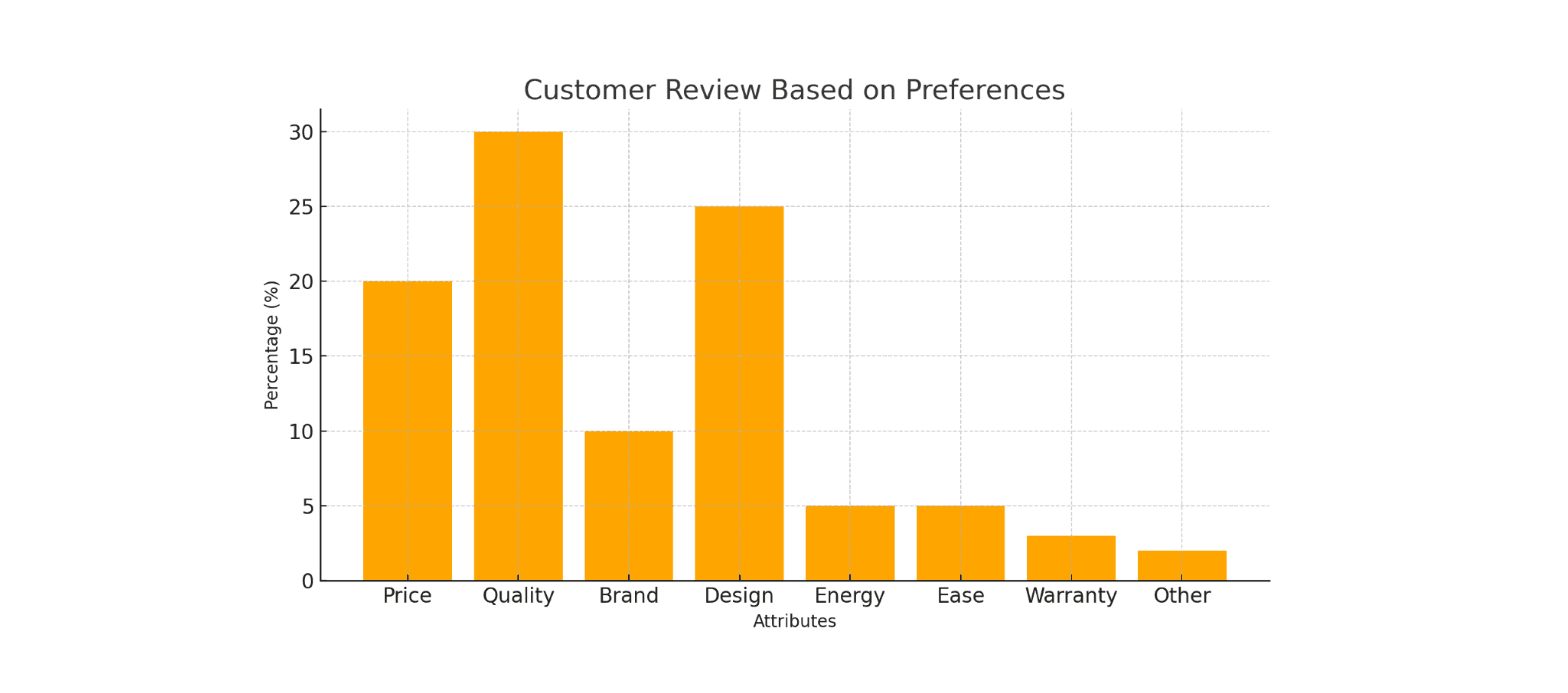

User Research

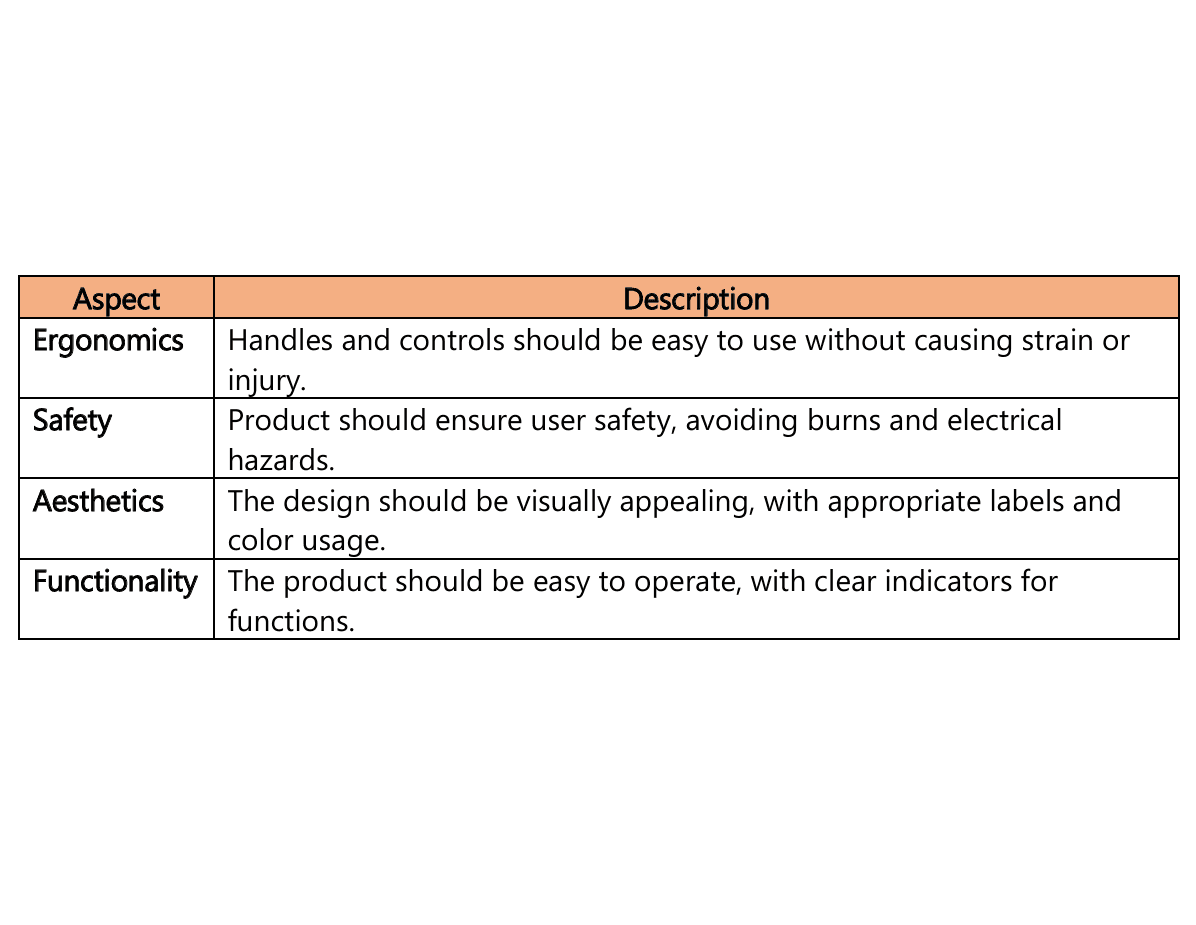

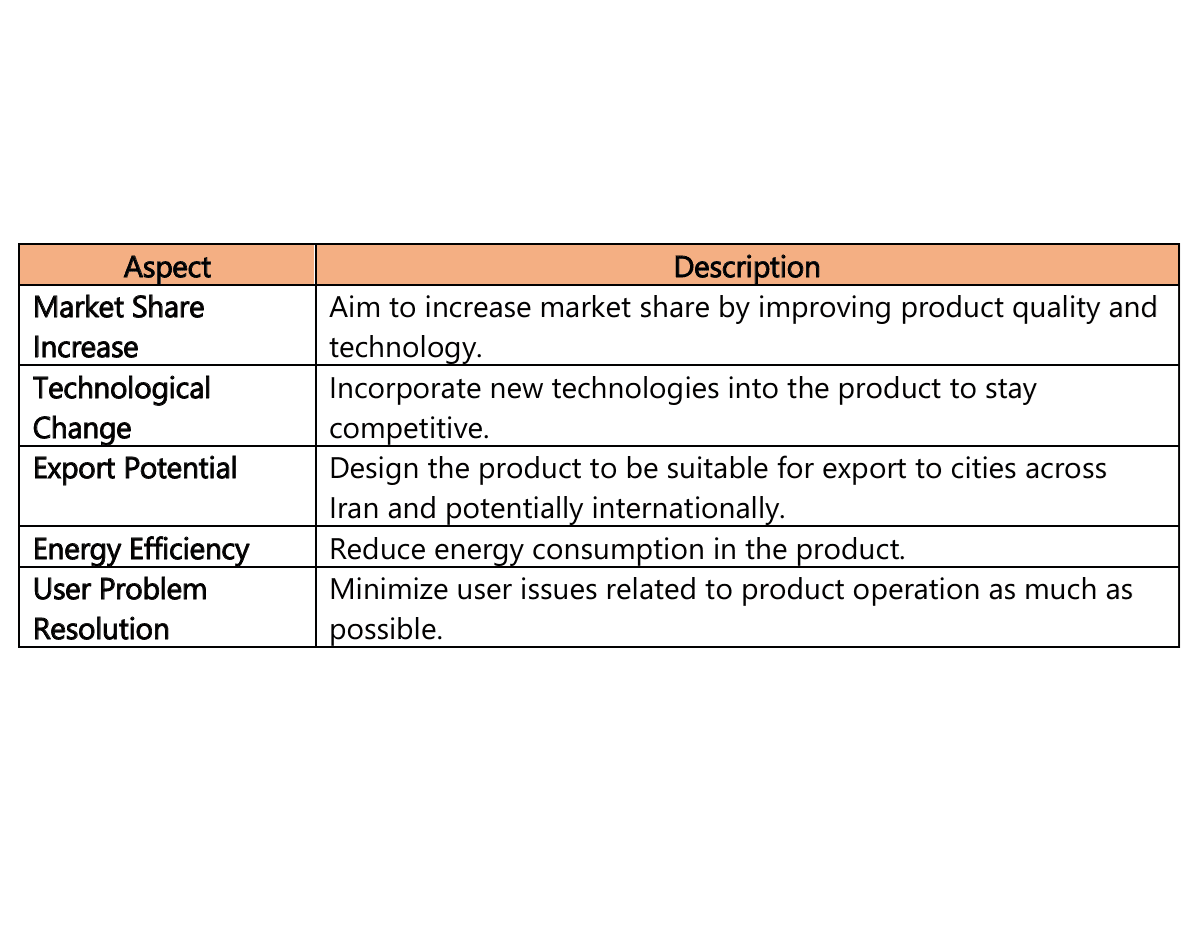

For this project, a comprehensive customer survey, conducted with over 100 respondents, assessed critical aspects of the product, including price, quality, design, energy efficiency, and ease of use. The results highlighted quality and design as the highest priorities for customers, with ease of use and energy efficiency also being significant considerations. Additionally, factory needs such as market share growth, technological advancements, and export potential were thoroughly examined. These insights were meticulously integrated into the final product design, ensuring that it meets and exceeds both customer expectations and factory objectives, aligning perfectly with market demands

User needs

Factory needs

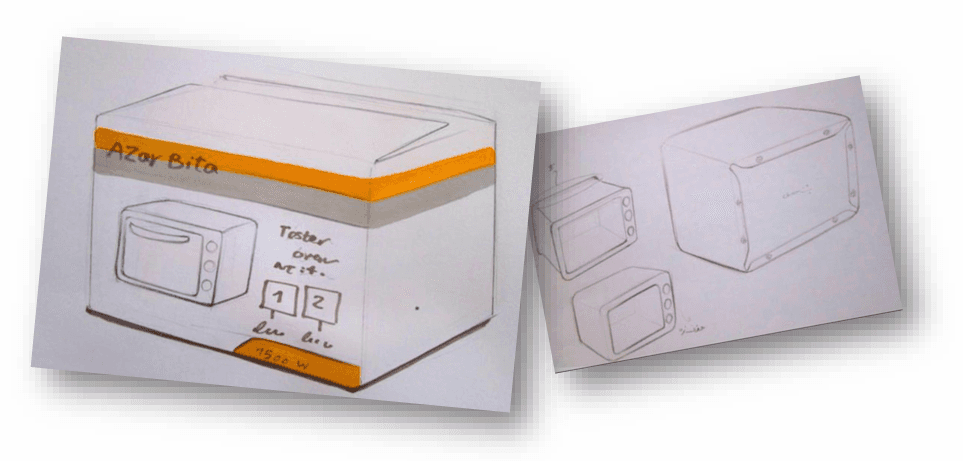

Idea and Sketching

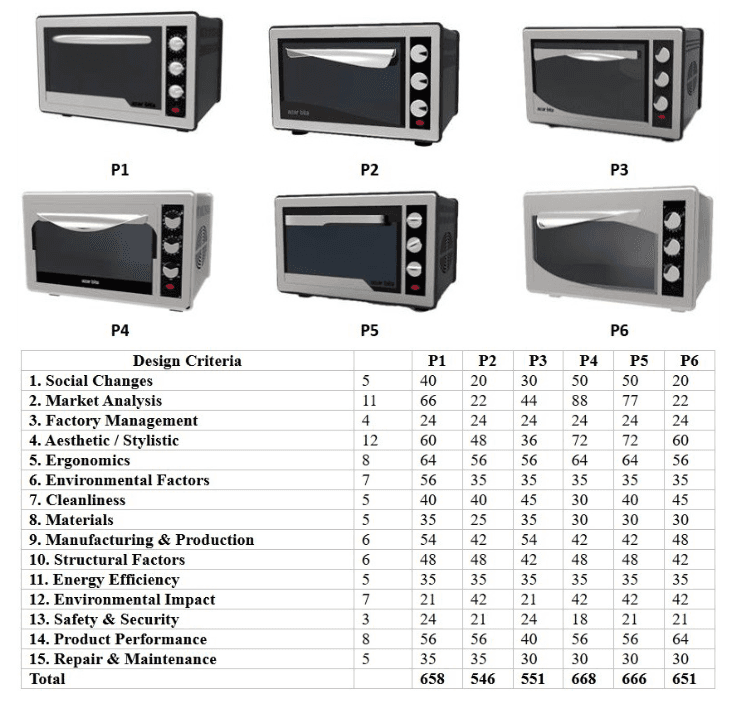

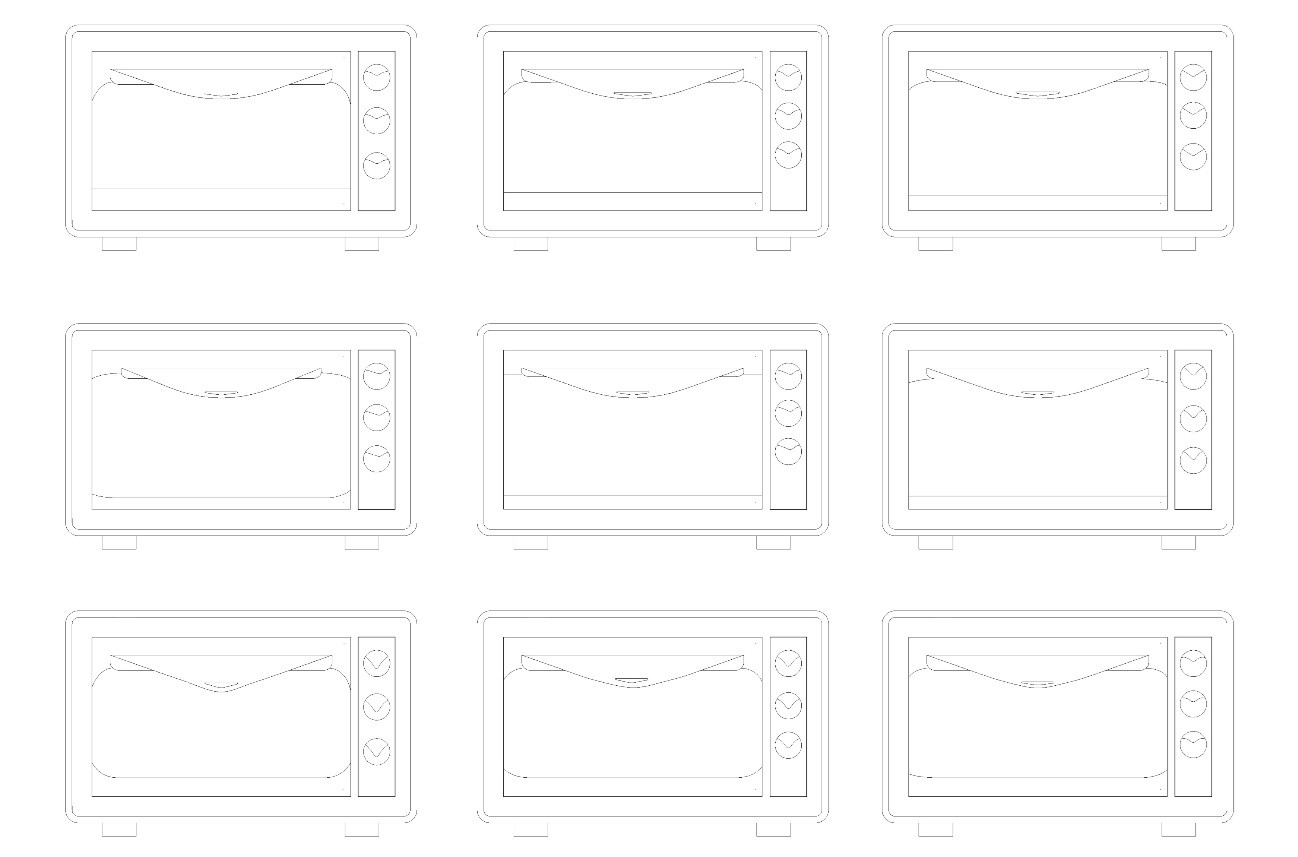

Prototypes 3D MODEL

Prototypes MODEL

Technical Drawing

Usability study Analysis

The selected steel color was chosen because users showed a stronger preference for it during the usability study. Additionally, the control dials and the oven handle were designed with ergonomic considerations in mind to enhance user comfort and ease of use.

Final Product Display

Conclusion

The oven design prioritizes user convenience and energy efficiency through several key features. The edges of the baking tray are curved to ensure easy handling, and the newly designed cake pan, which was not available in previous models, is adequately sized for three servings. The use of stone wool instead of fiberglass as insulation effectively prevents energy loss. An interior light helps reduce energy waste and prevent food from burning. The application of a Teflon coating on the interior surfaces simplifies cleaning, while a fan ensures even cooking. The design harmonizes the form of the handle with the control dials. Additionally, the stop mechanism is implemented to prevent breakage, and the choice of black for the background with white for numbers and symbols enhances accessibility.